Cardboard can warp when painted. This happens because when the paint dries it constricts the cardboard on the side that was painted. This tightening of one side make a concave shape on the painted (constricted) side. The warping generally is opposite to the corrugation in the cardboard. Corrugation is the ridges or waves of paper in the middle of the cardboard. The corrugation keeps the cardboard from warping in one direction but only in the direction the ridges run. To flatten it out you need to add reinforcement the opposite direction of the corrugation. There are a couple of solutions; all of them involve gluing cardboard to the underside of the warped piece making sure the corrugation of the reinforcement is perpendicular to the existing/warped corrugation.

This method is the strongest and will correct most warping. It involves bending a piece and bracing it to give it extra rigidity. The bend gives the piece a connected corner the whole length which gives it strength in more than one direction. This brace only works if your section is elevated. If you look closely you can see that the corrugation is running lengthwise. This takes advantage of the cardboard natural strength and it also allows us to bend it straight down a ridge. If don’t have room for a full brace under the warped section a wide strip of cardboard glued with the corrugation perpendicular to the warped section should straighten it out a lot.

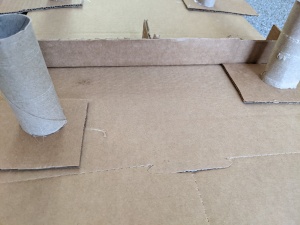

See here how much this section has warped. This is before we glued down the brace. Look at the direction of the corrugation on the warped base piece. We are going to lay our brace with the corrugation going perpendicular. The ball would most likely roll down the center of the course because of the warping.

Here is a picture with a brace glued down. See how well it flattened out the warping. If don’t have room for a full brace under the warped section a wide strip of cardboard glued with the corrugation perpendicular to the warped section should straighten it out a lot.